Home / Capabilities / Machining

Machining

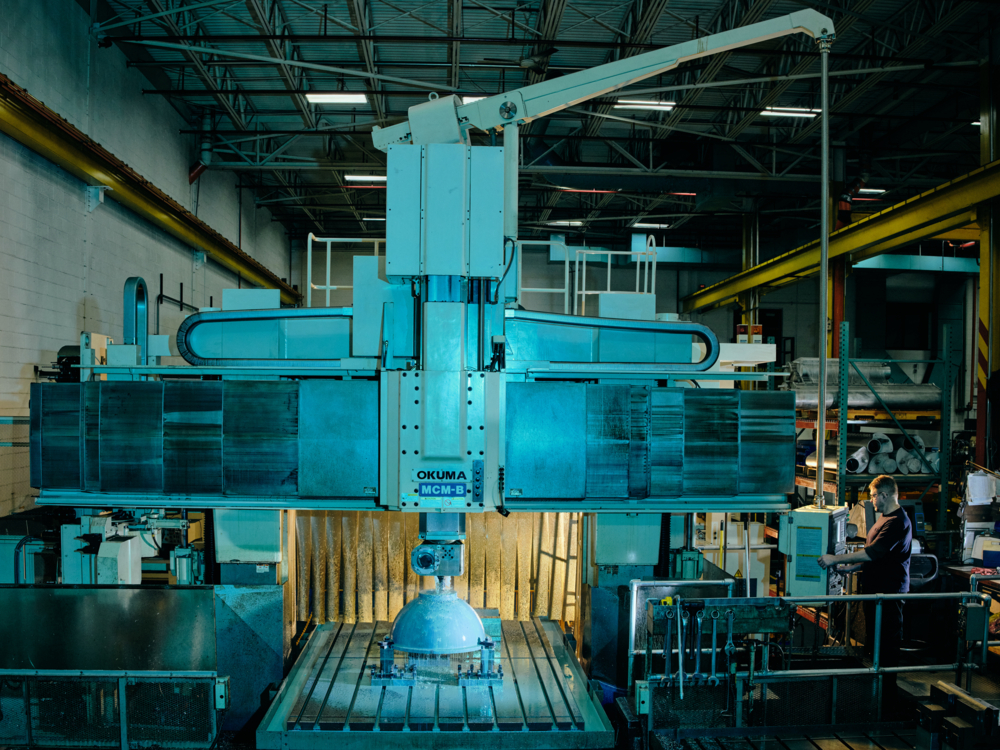

Large machining

Our Okuma mill is one of only a few in the state of Wisconsin. The large envelope can do five-sided milling on parts up to 149″ x 76″ x 39″ high. Almost no job is too big for this mill.

Gantry Mill – Okuma MCM-B-25E

Our gantry mill allows us to machine more robust products with its large work envelope. With five-sided machining capability and a 50-tool magazine capacity, the gantry mill gives us the ability to better serve industry’s heavier equipment needs.

- Single-spindle five-sided machining capability with 5-degree indexing

- 192″ (X) x 96″ (Y) x 31″ (Z) x 39″ (W) vertical work envelope

- 163″ (X) x 96″ (Y) x 31″ (Z) x 39″ (W) horizontal work envelope

- Two 149″ x 76″ tables with automatic pallet changer

- 50-position tool changer

- 30 HP motor

- Spindle probing for part setup and inspection

High volume machining

We utilize our Fastems Flexible Manufacturing System for the high-volume and high-machine time parts our customers require. Each of our 48 pallets can fixture parts on four sides. We can really reduce costs on your high-volume or very complicated parts. Are you importing from China? Send us your parts and we’ll build them domestically!

Flexible manufacturing system (FMS)

Our flexible manufacturing system is equipped with 2 Okuma MA-50 Horizontal Machining Centers and a 48-pallet storage and shuttle system. The system gives us the ability to run 24 hours, 7 days a week with night and weekends operator-free.

- Fastems 48-pallet storage and shuttle system

- Two load stations capable of running 24/7 “lights-out”

- Two Okuma MA-50HB horizontal machining centers with:

- 27″ (X) x 31″ (Y) x 27″ (Z) work envelopes

- 500mm x 500mm pallet changers with 1-degree indexing

- 12,000 RPM, 27 HP motors

- 200-position tool changers each

- Probing for tool setting and tool breakage detection

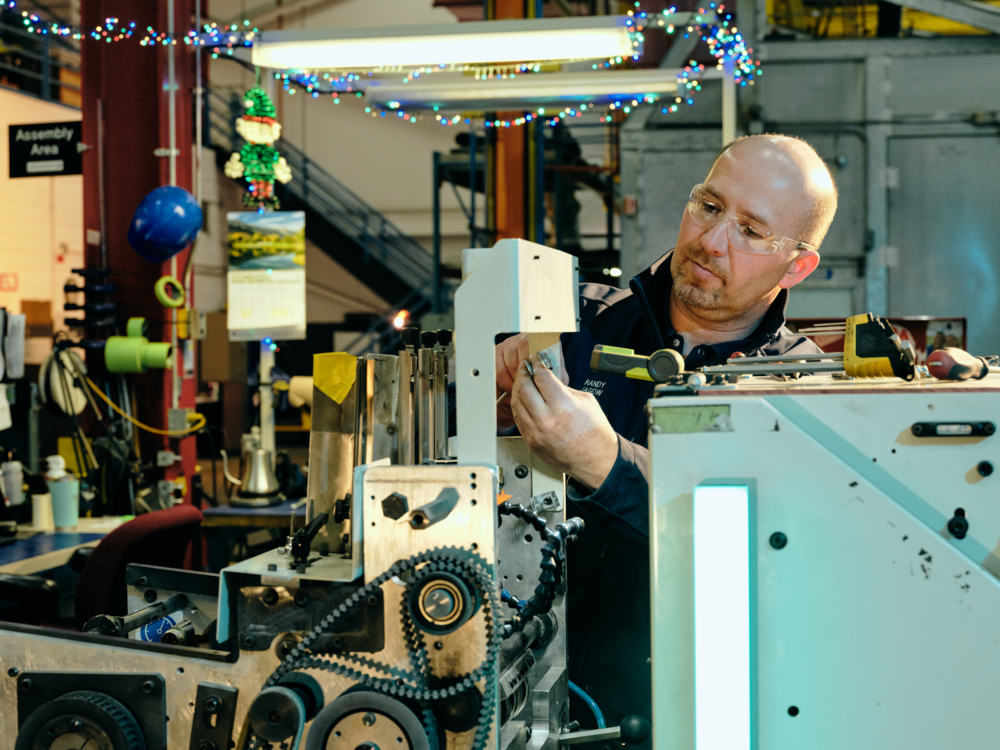

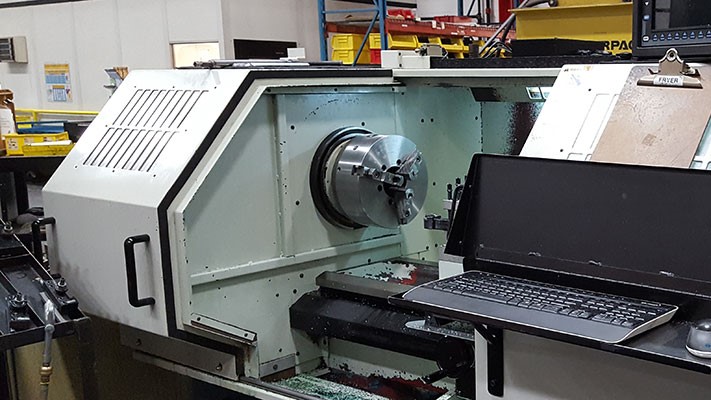

Short-run & prototype machining

Our machine shop offers several CNC and manual milling and turning machines. We utilize our home-built CNC online software to deliver the right program to the right machine. Our core business is running short-run, quick-turnaround, and prototype machining. We can work with your engineers to develop the prototype parts you need.

Short-run & prototype equipment

CNC Machine Tools

- Daewoo DMV400 CNC vertical machining center

- Haas VF2 CNC vertical machining center

- Atlas 4B-VSCNC-40 CNC bed mill

- Mori-Seiki SL-25 CNC turning center

- Trak TRL 2460SX CNC Lathe

Lathes

- (4) Clausing/Colchester engine lathes with up to 21″ dia. x 120″ length capacity

QuadMetalworks, a Quad division, has been one of our most consistent and best suppliers, and more than that they are a partner to our business. They support us with production level quantities and prototyping work. They are always open to jumping through hoops to meet our deadlines and always are suggesting design improvements that will help us lower costs.

— Adam Walters, Procurement Manager, Pregis LLC

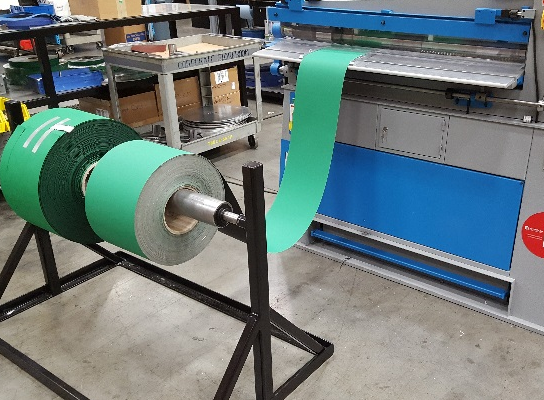

Explore our other capabilities

Our fabrication job shop specializes in medium to large-sized structural steel welding.

Our belt shop makes Forbo/Siegling, Nitta, and Habasit skived and finger spliced belts.